Creating My Custom Pedal Board

Sometimes I give myself a project that requires a physical build. These personal projects are rewarding since I am constantly making virtual things ...so when I get to make a physical one, it gives me a whole different level of satisfaction.

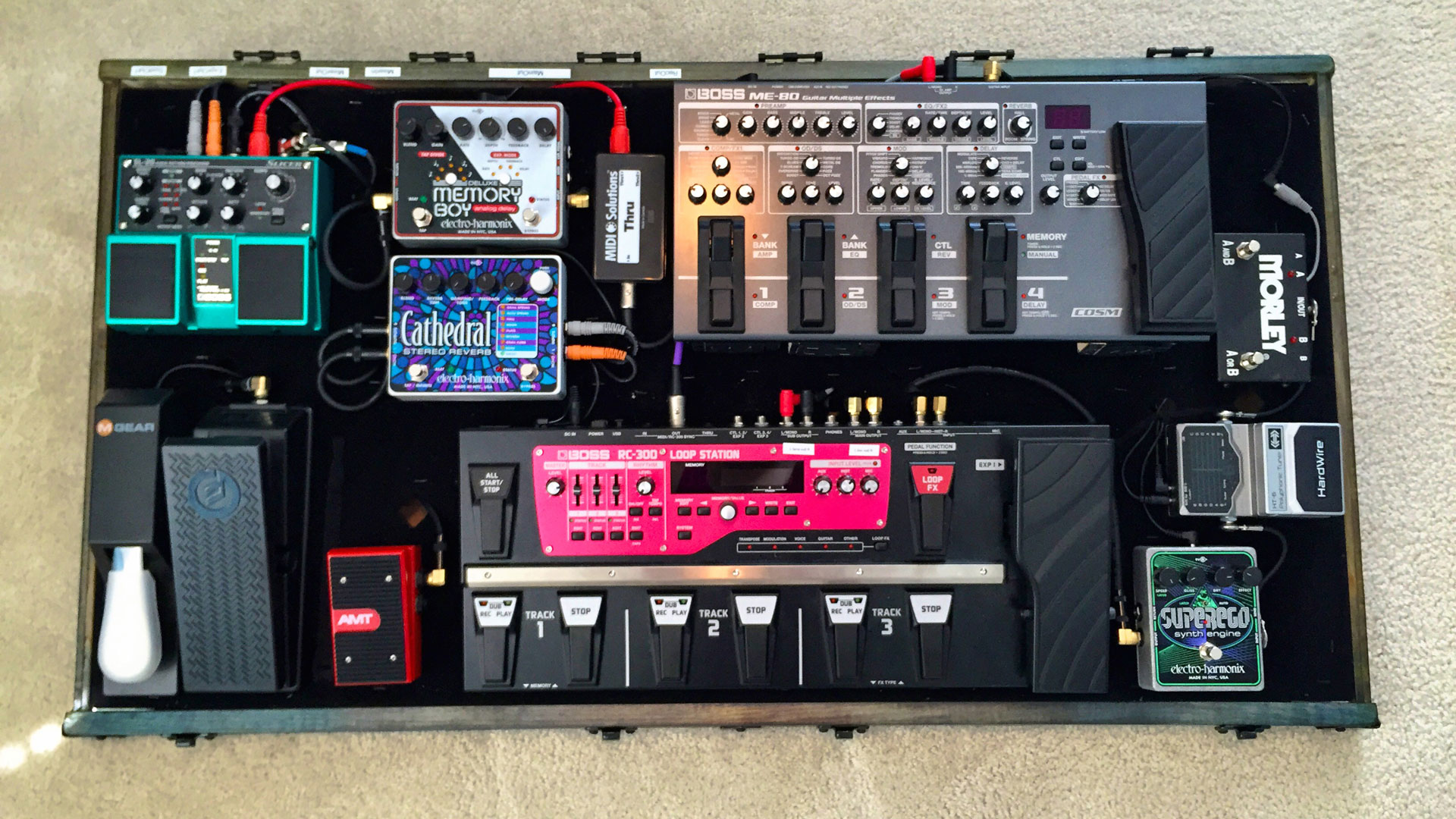

The goal of this project was to make a housing for a large array of effects pedals, so I wouldn't have to worry about hooking them up when they were moved. This often takes lots of time and troubleshooting to gets things up and running.... a process that can totally kill the mood for playing.

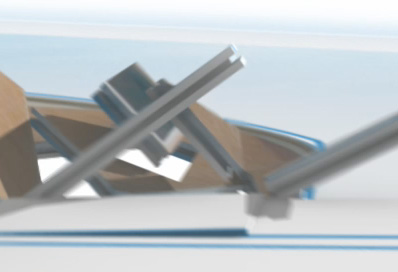

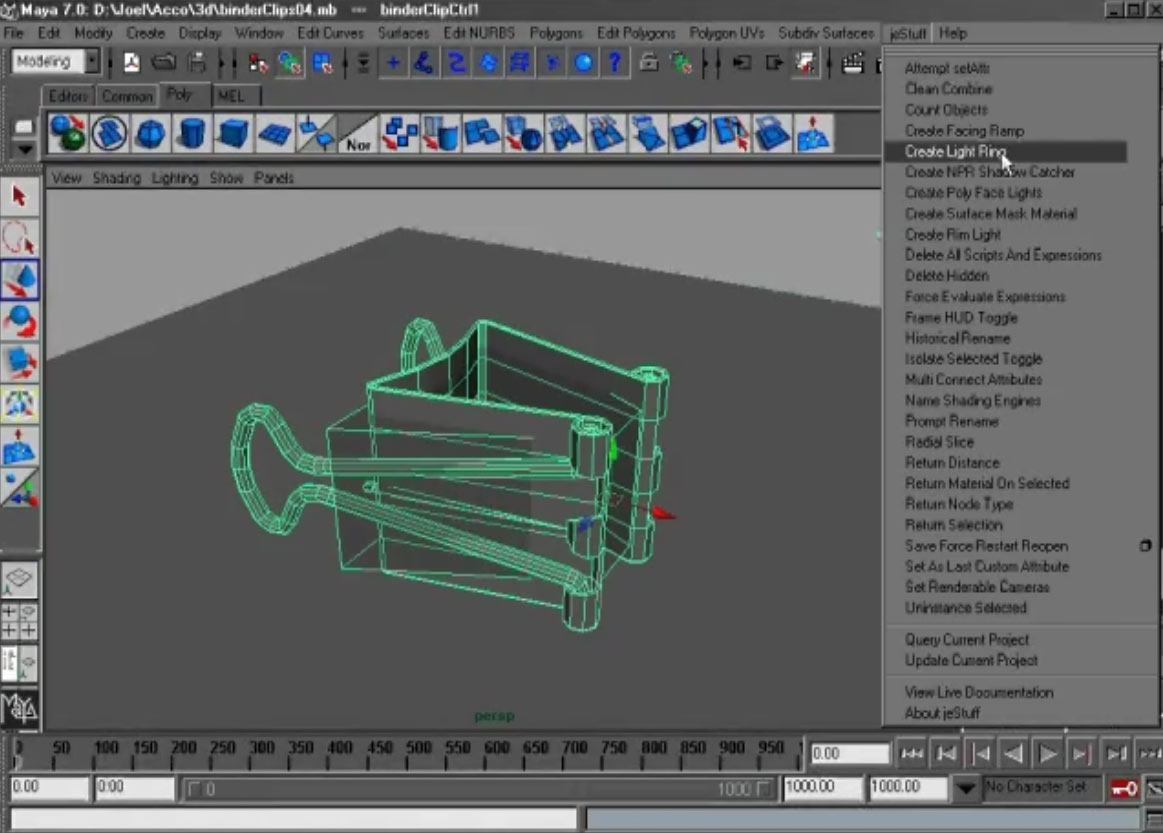

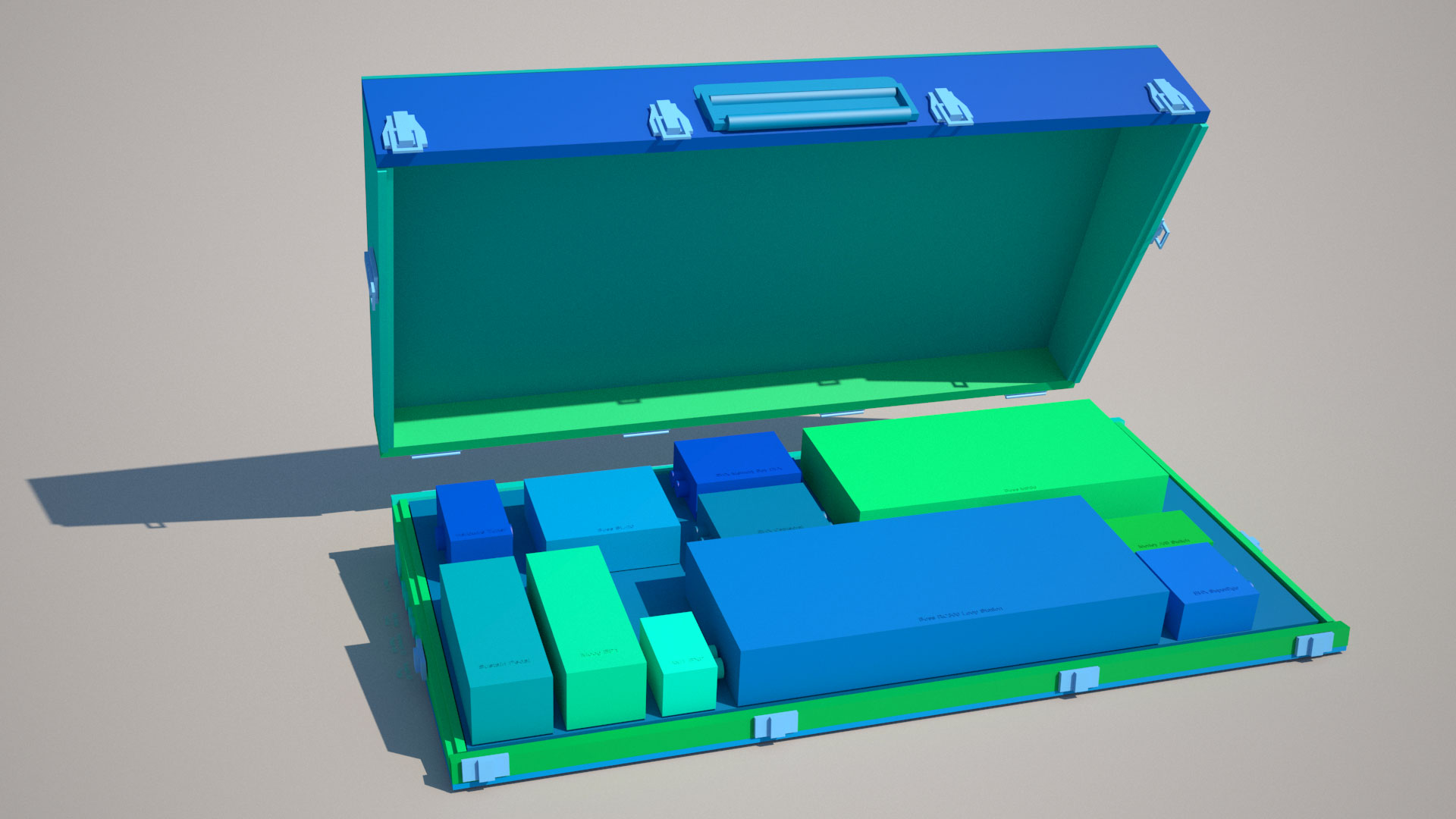

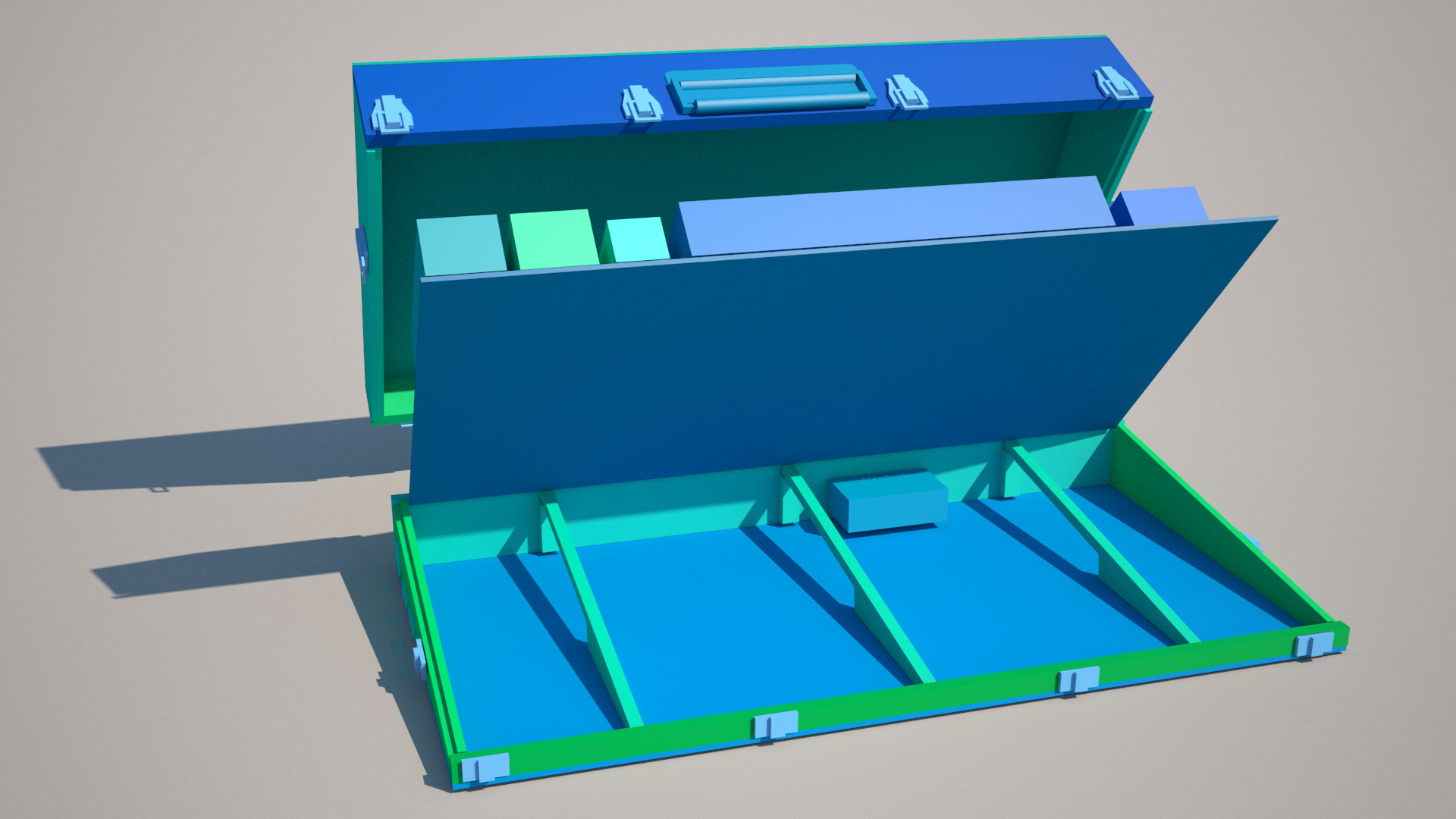

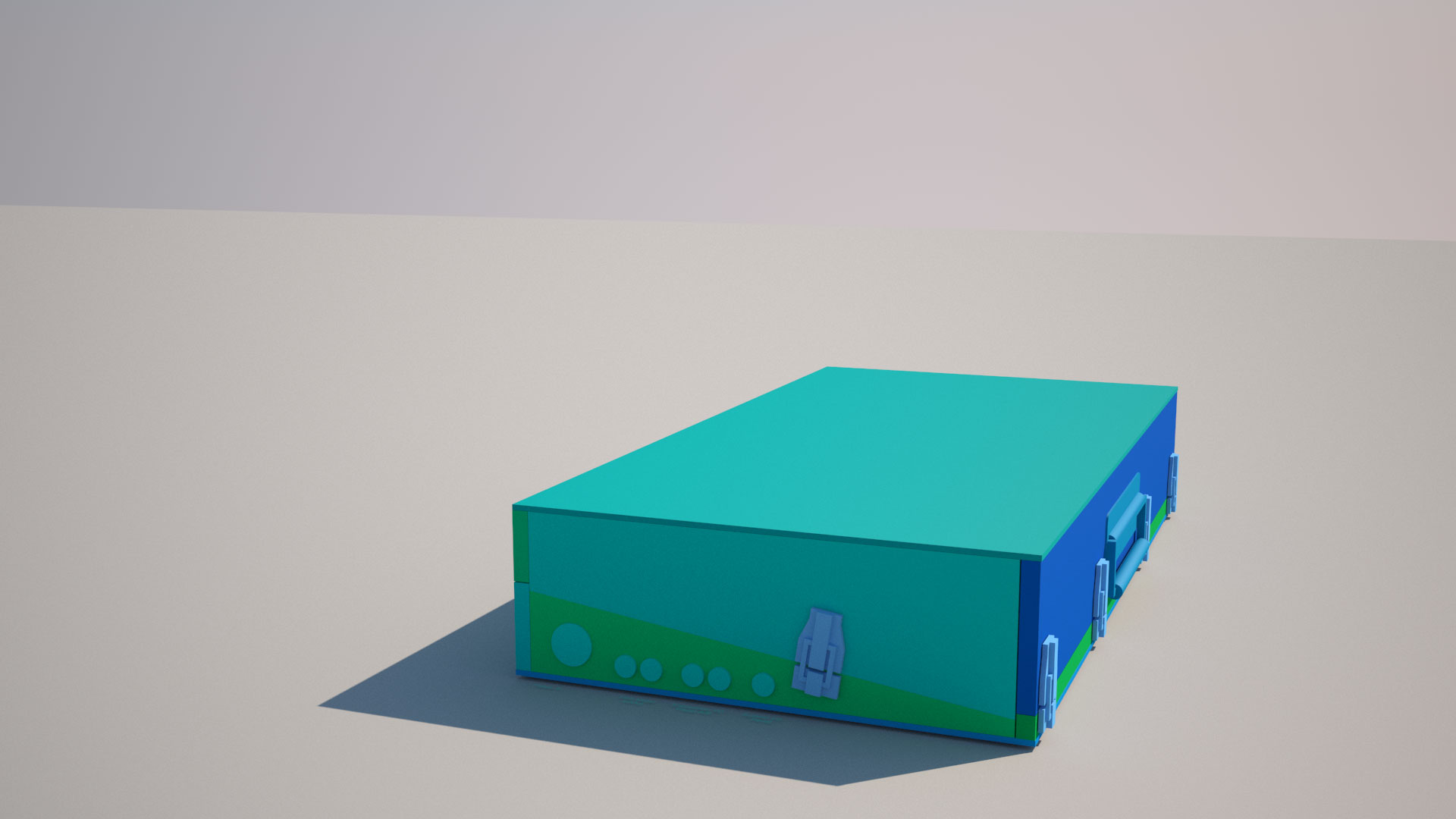

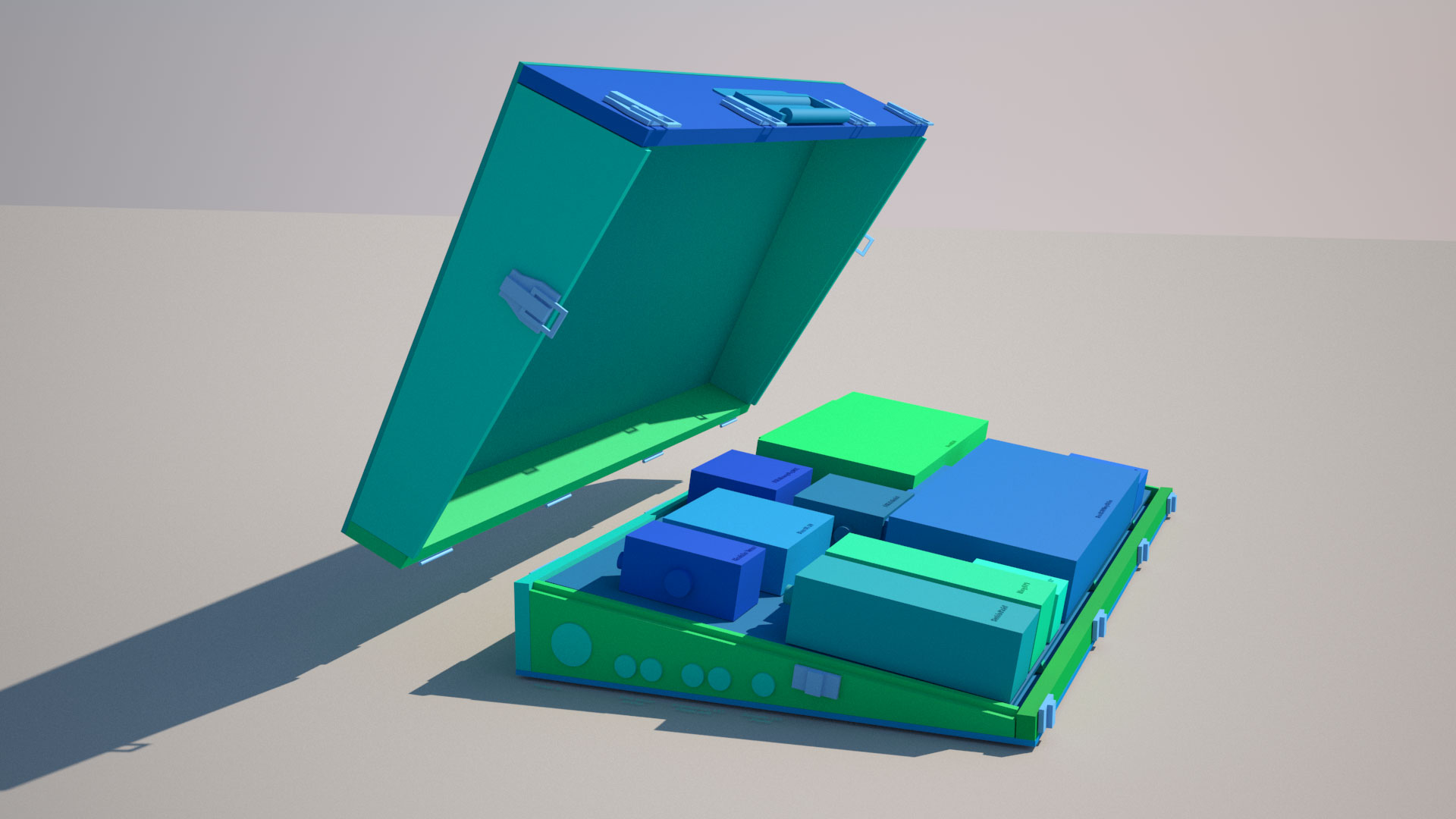

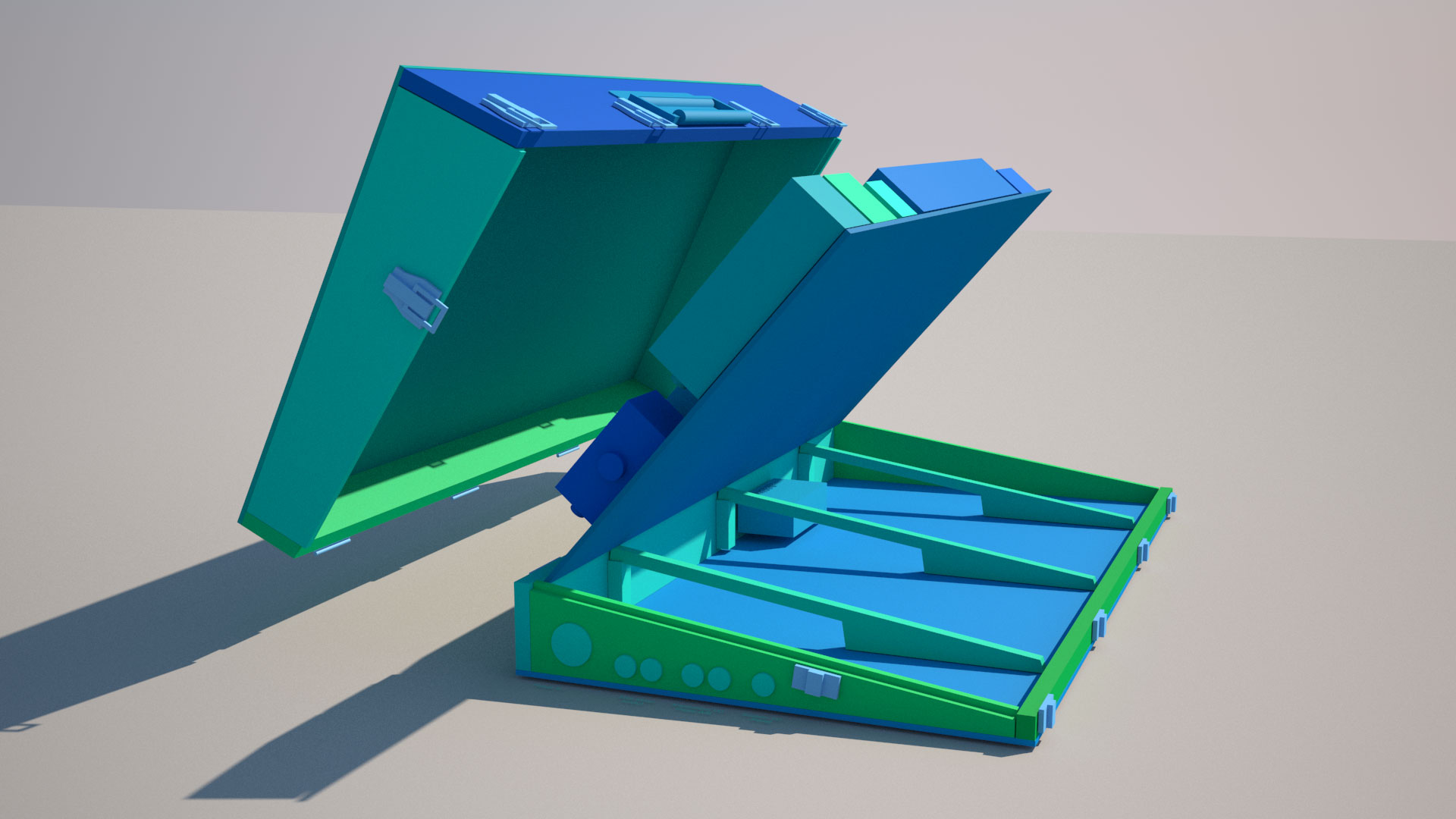

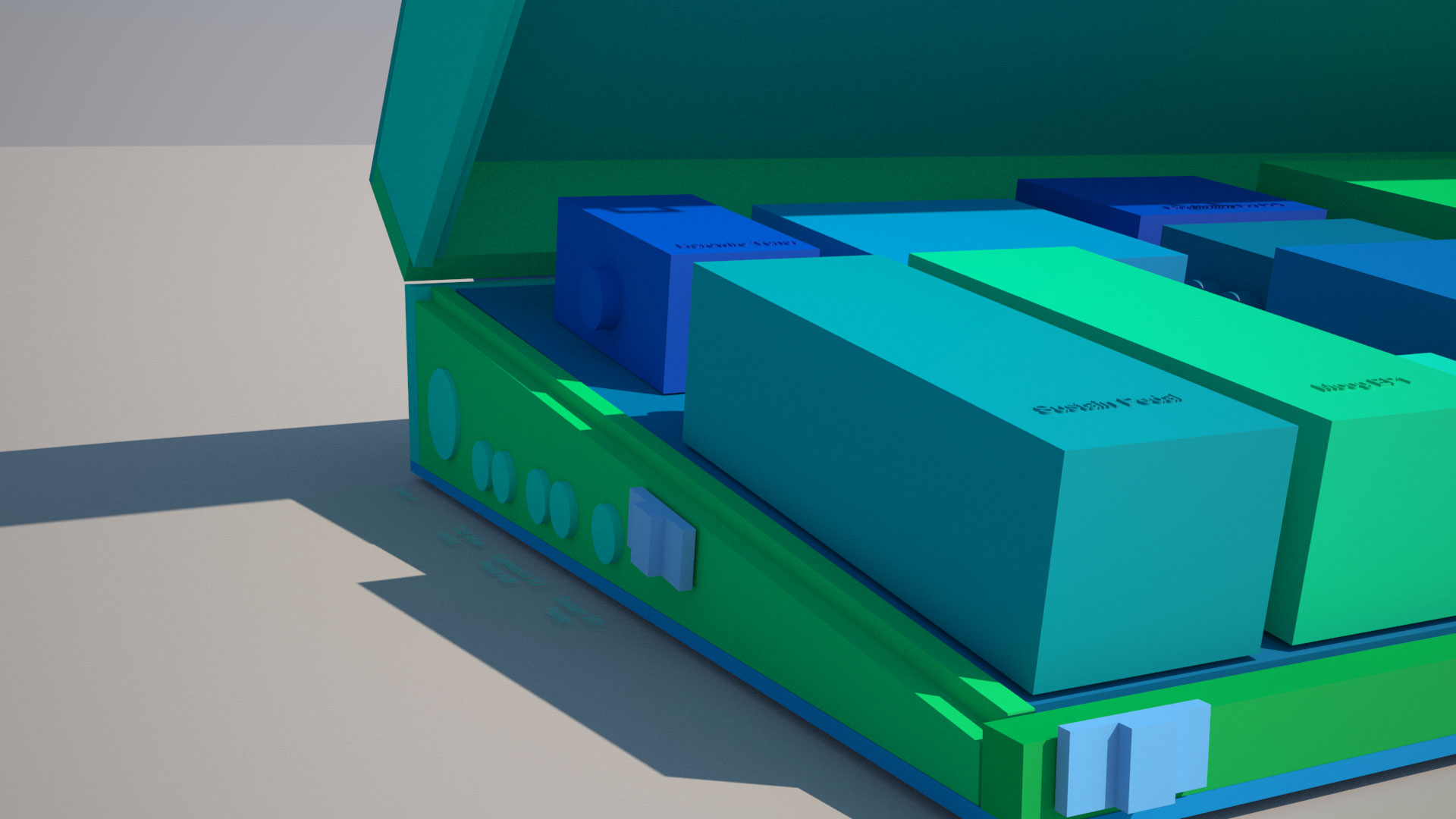

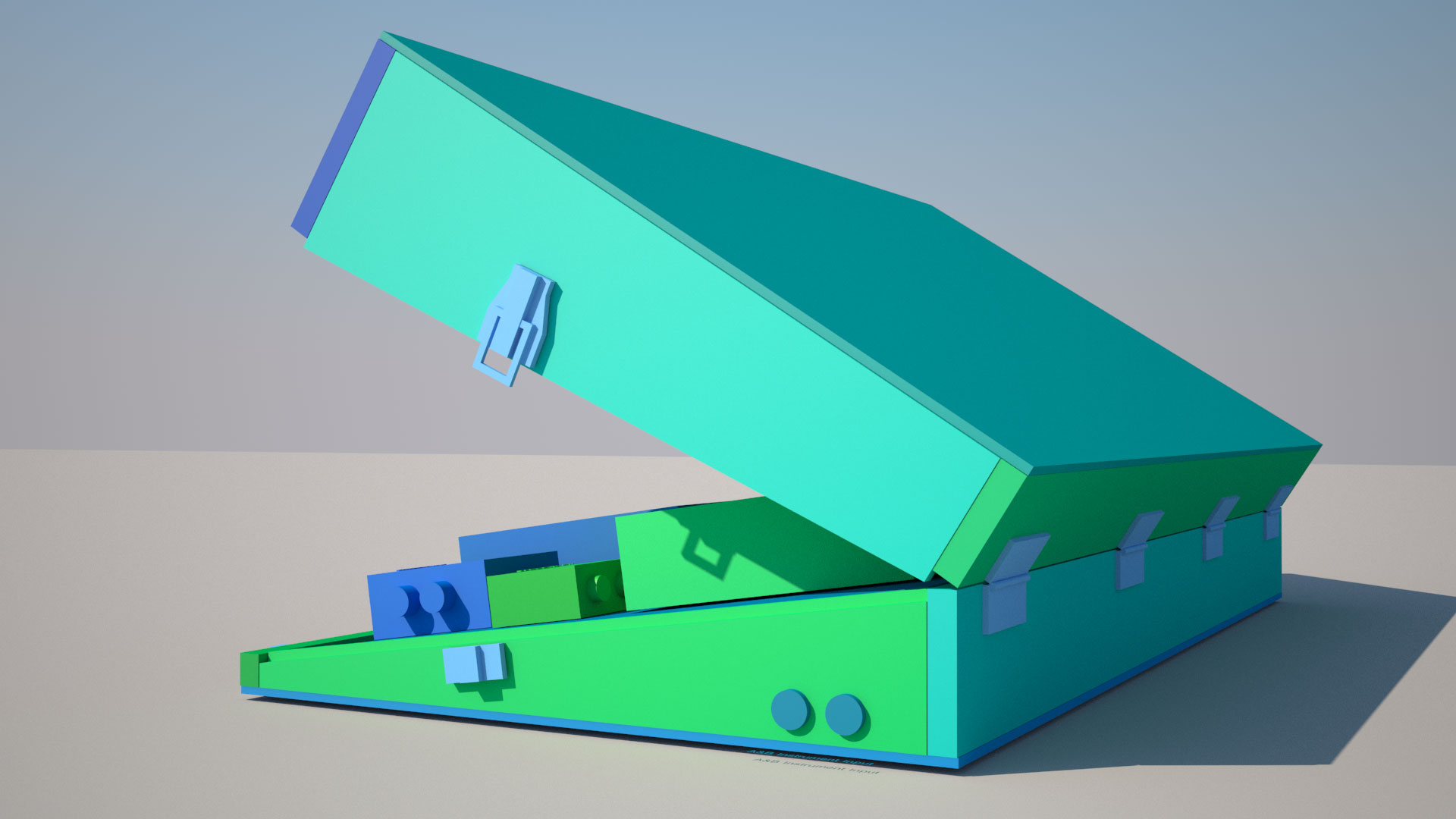

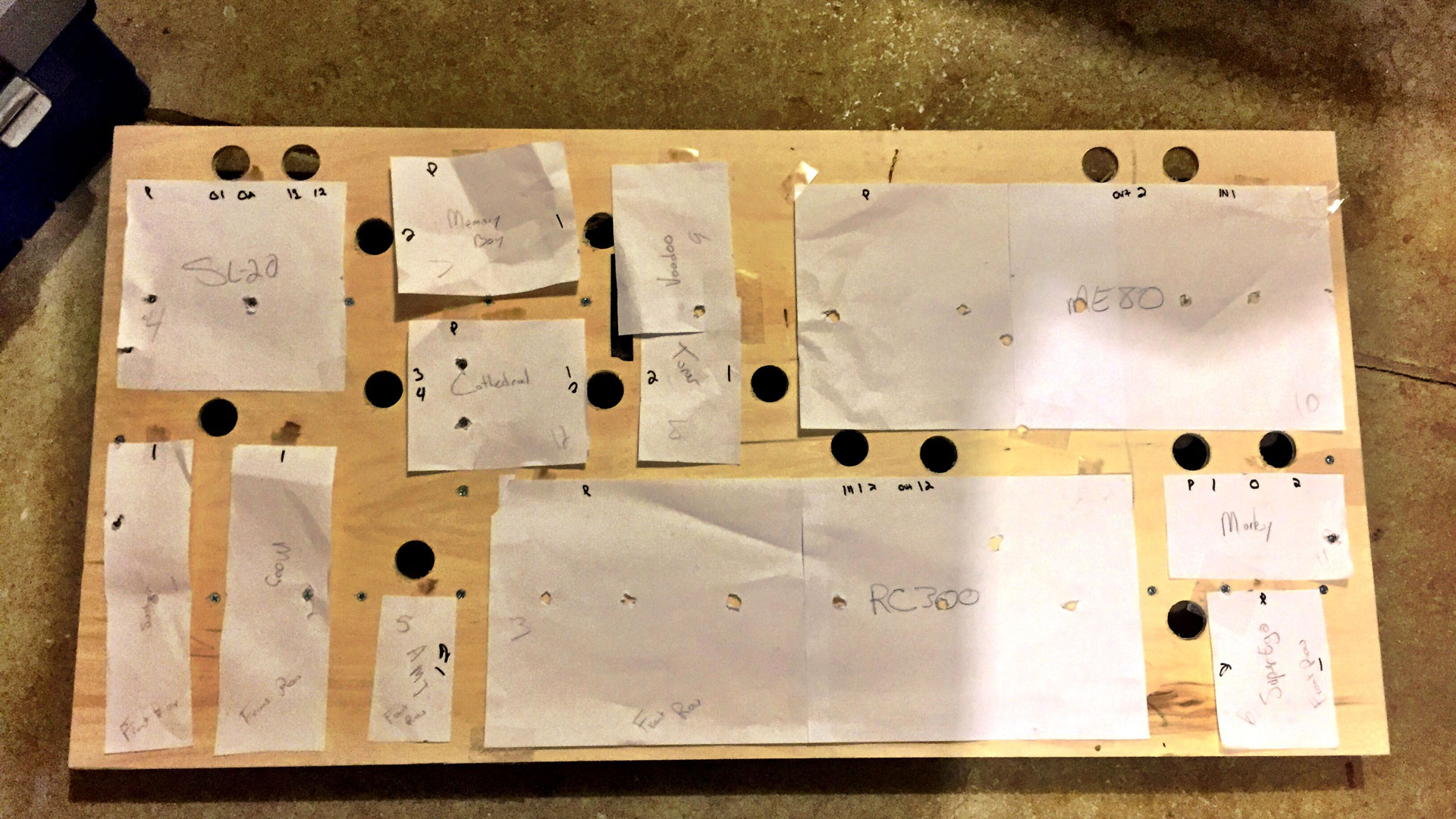

Modeling The Monster

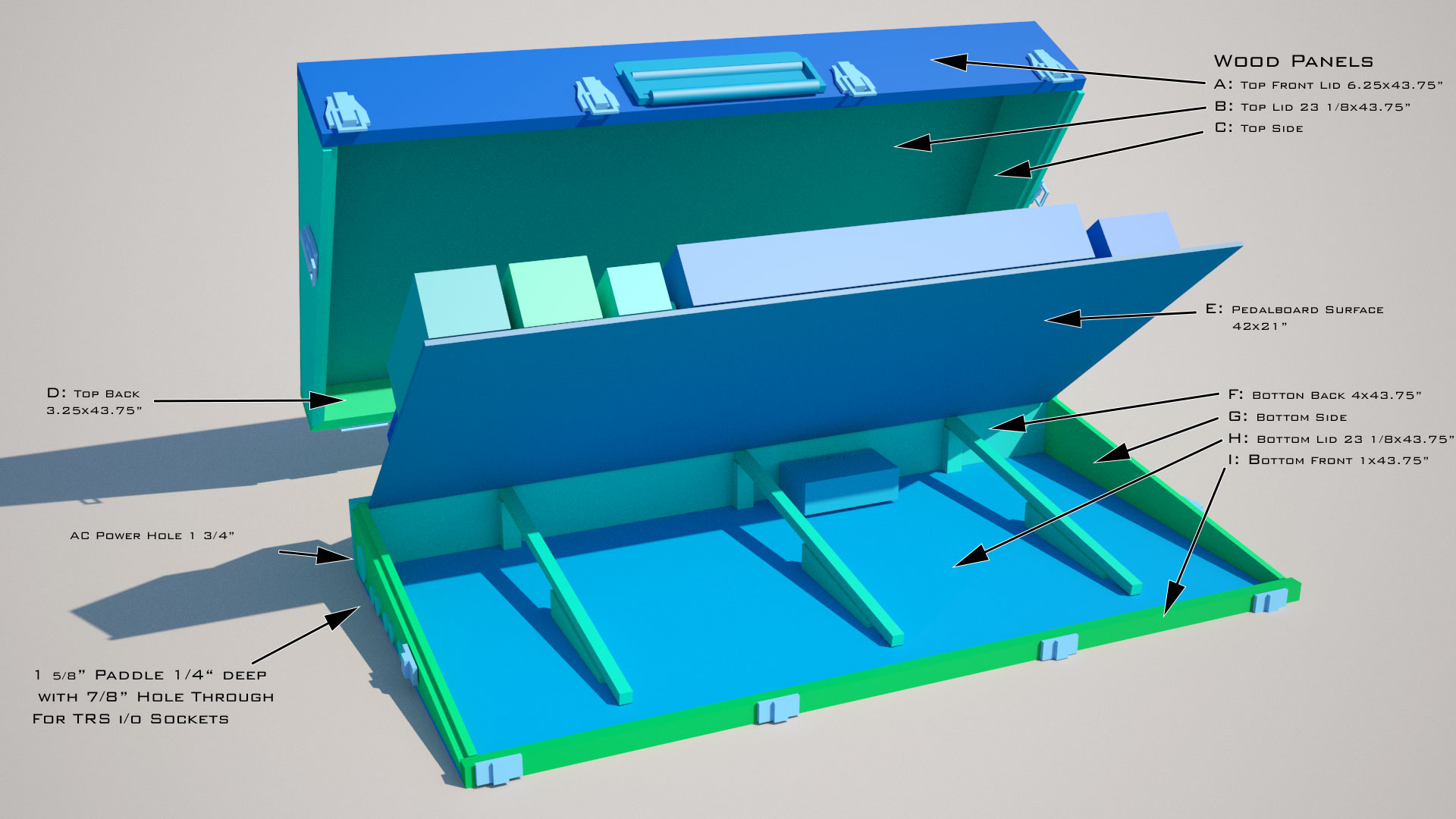

When I originally started, I didn't know if I would be able to make it as nice as I had planned, but it actually came out even better than expected. I started in 3D Studio Max with simple shapes. I just needed to represent volumes, so materials and lighting didn't even need to be considered. I just needed to reassure I had the right dimensions and i would be able to cut everything accuratly, just once... since fancy cuts of wood are expensive. I knew it would be large but didn't really care. I created paper to represent each pedal, and was able to move them around quickly to find a good configuration and density within the space while still leaving room cables and fingers. Below you can see the modeling stage of the project, where i was able to determine all sizes and materials needed.

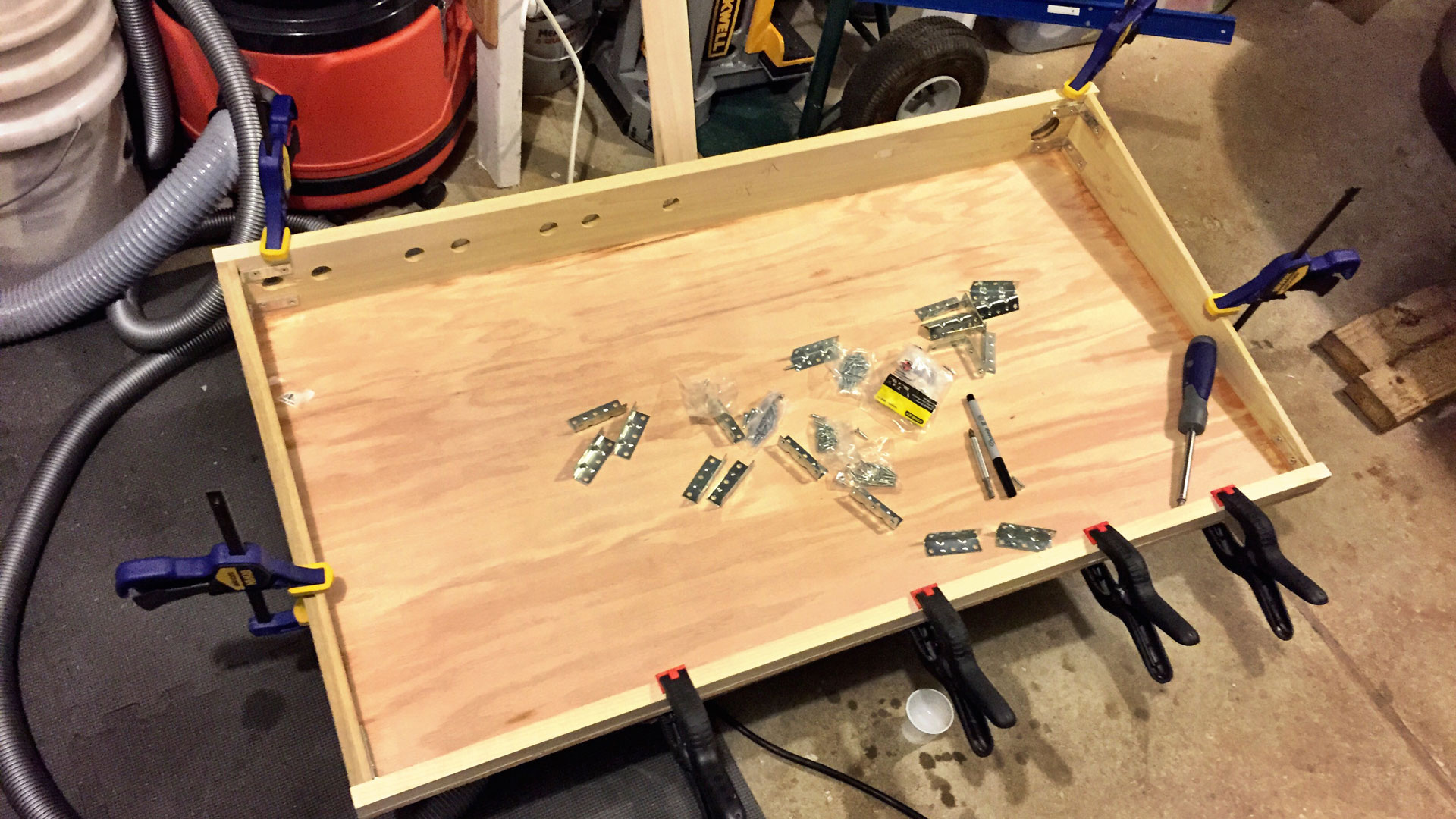

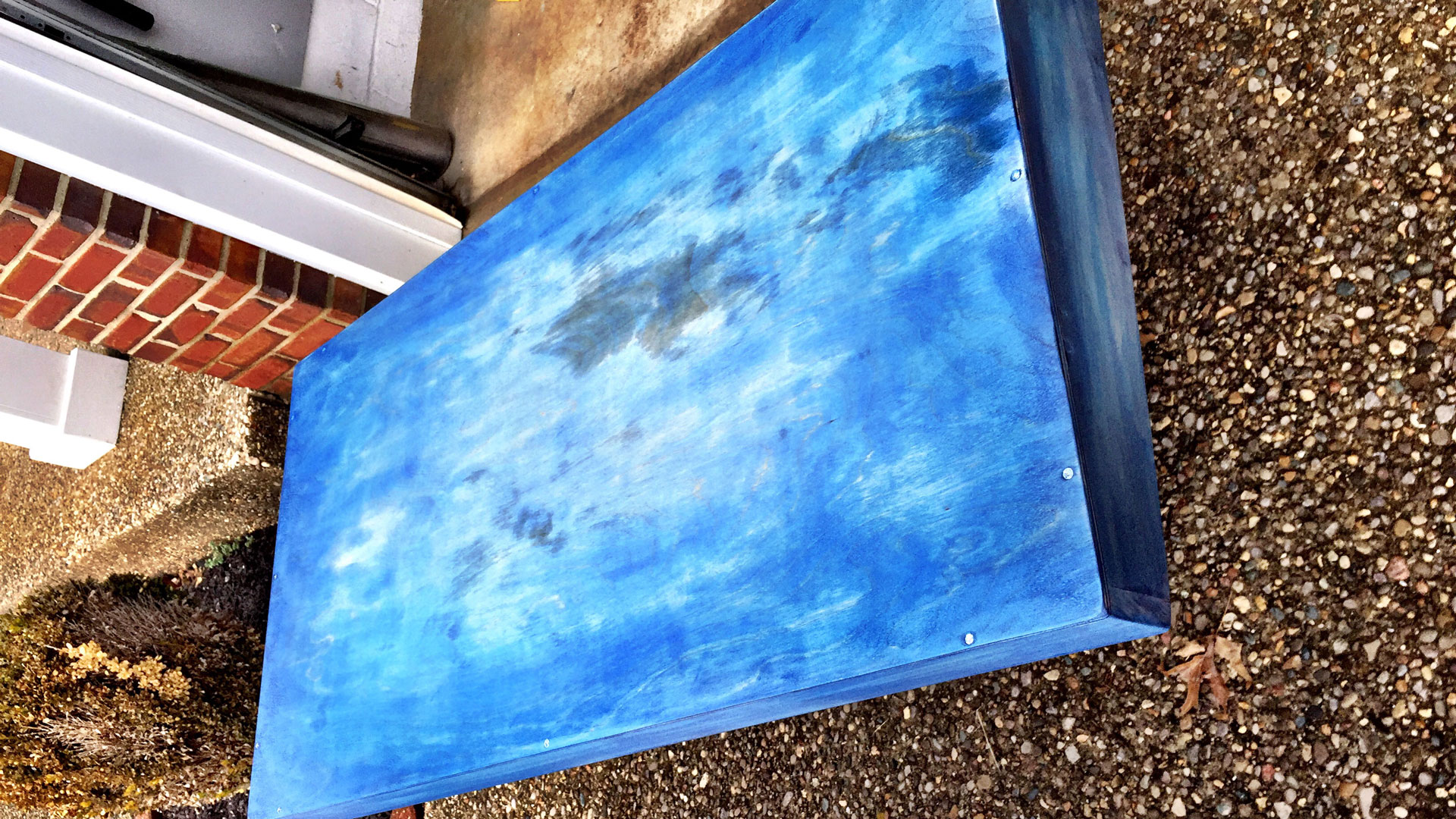

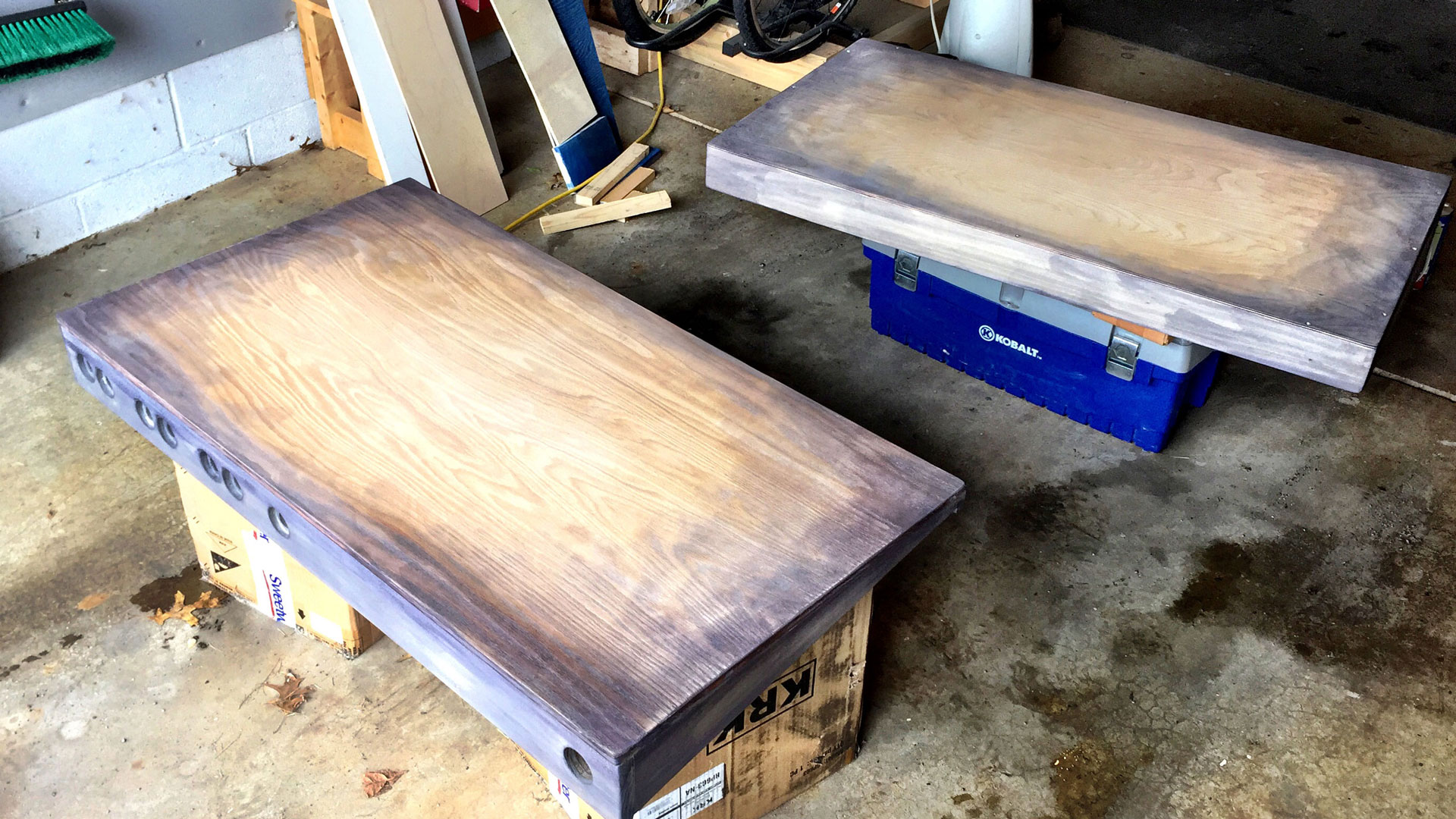

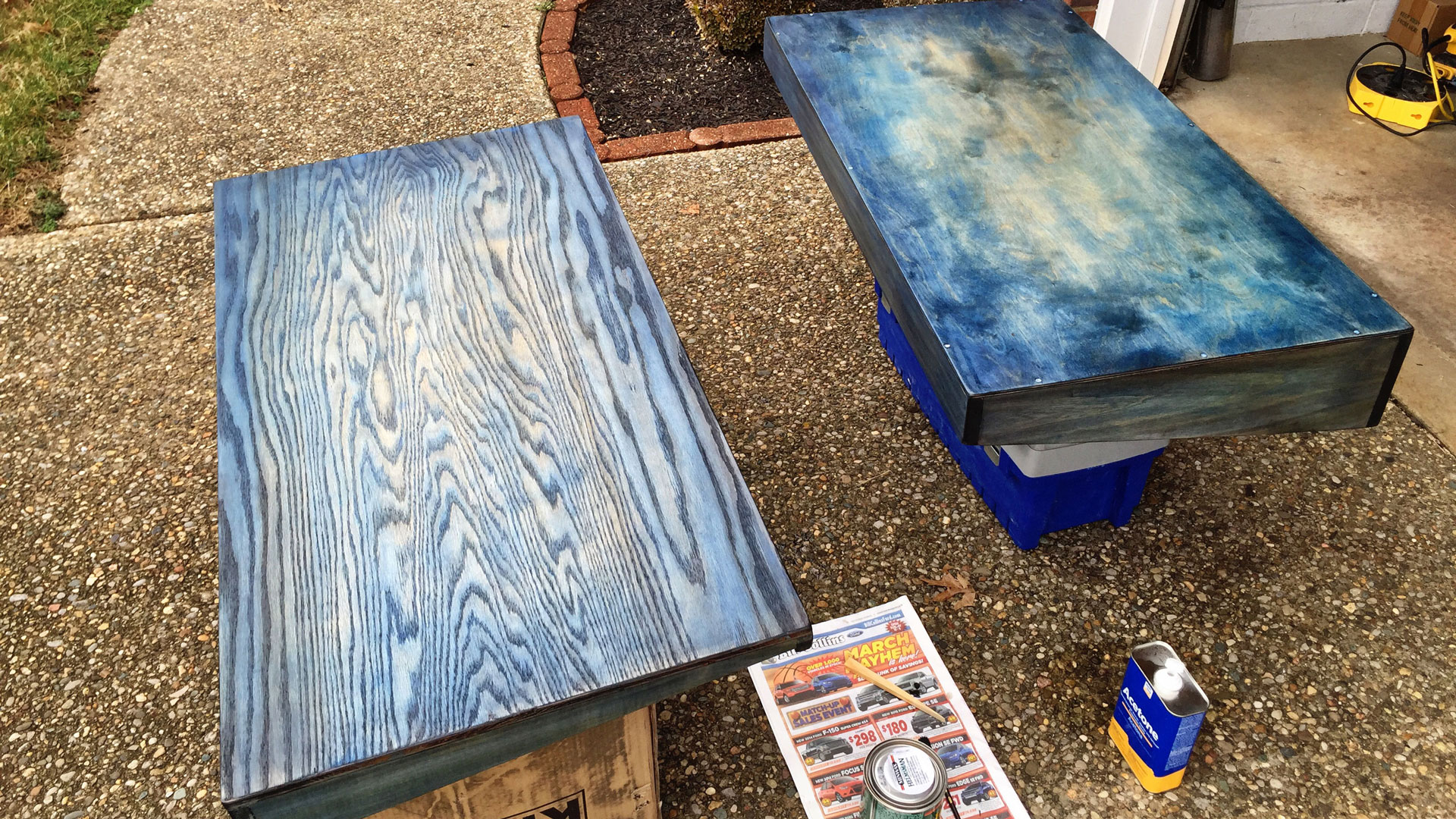

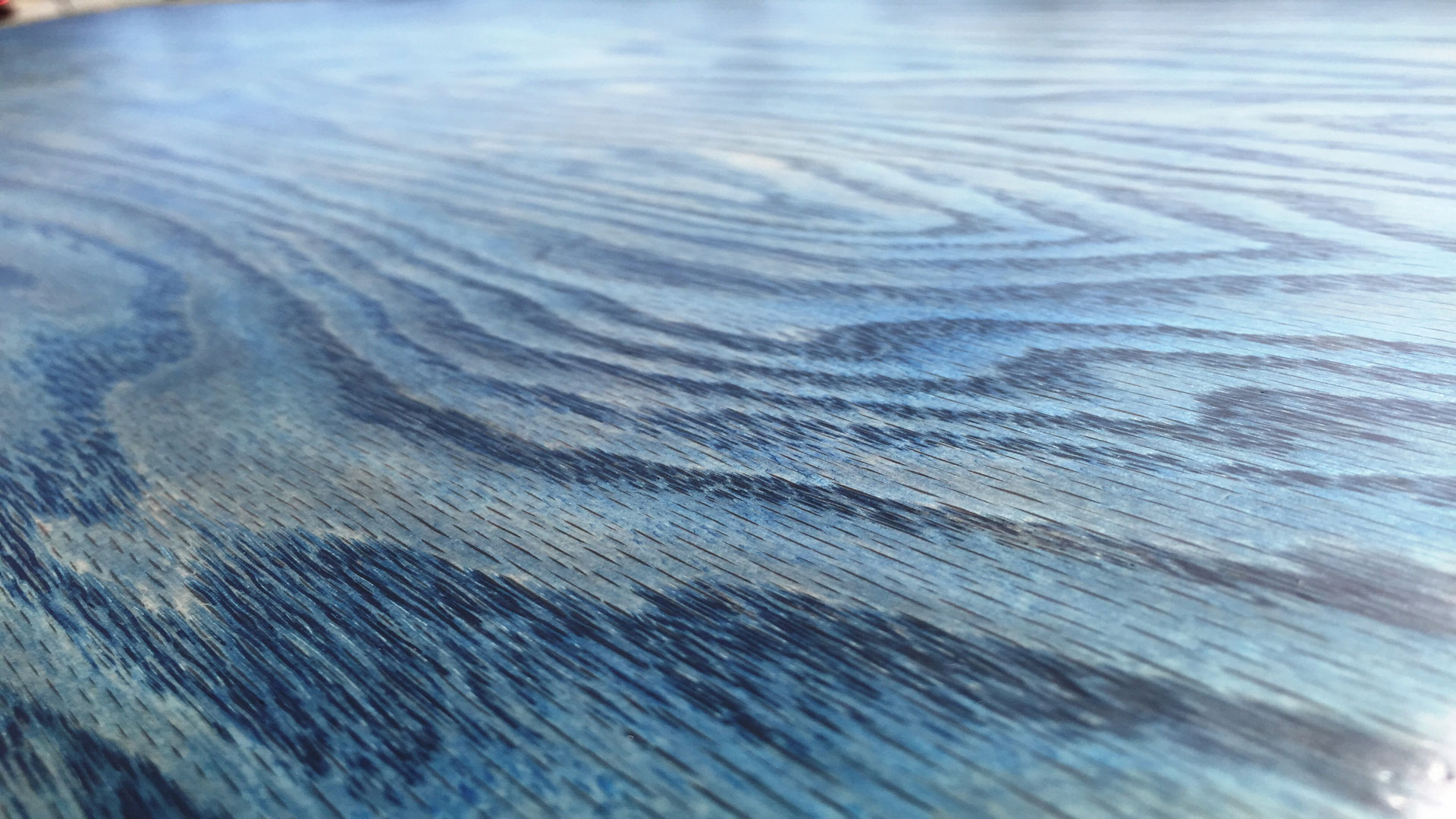

Building and Finishing

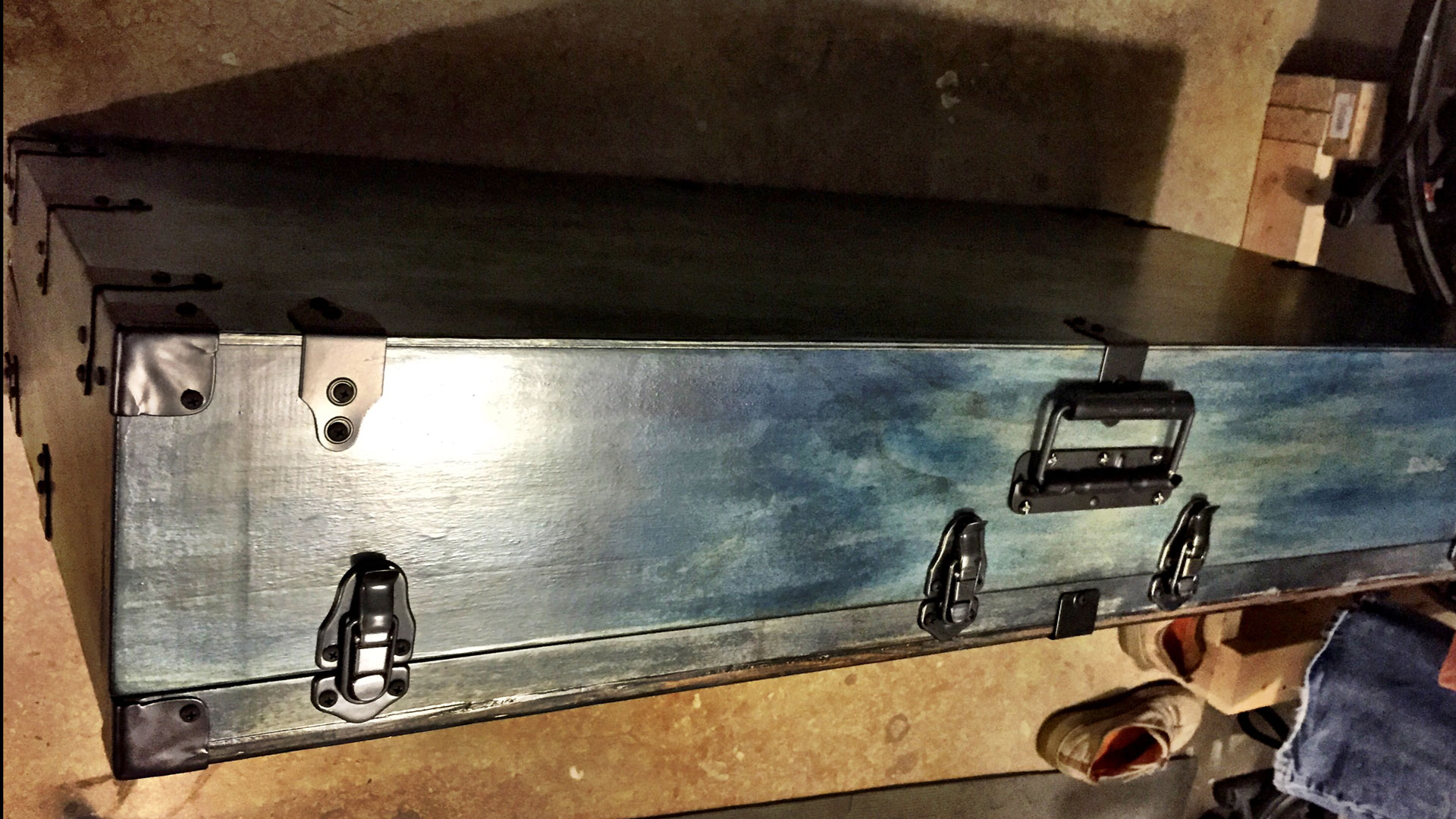

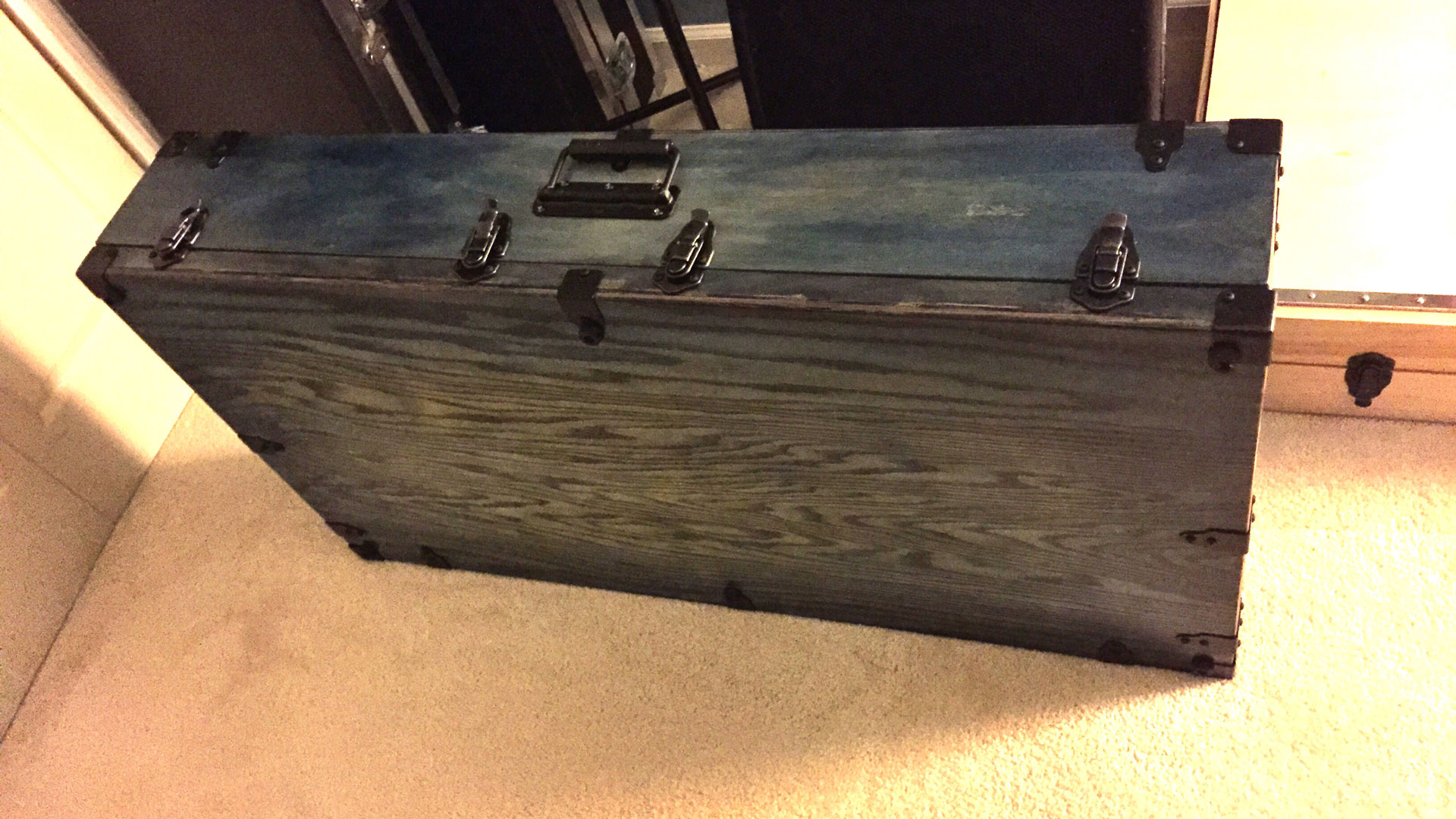

This is the first time I ever tried to tint wood, it is also the first time I've ever tried to add a manual fade. Dye is more potent than stain and add can a more interesting finished look. In short, what you see below is me dying the entire box blue, multiple times, making it very strong. Then, I hand sanded away the core, creating a bit of a fade around the edges. The oak bottom worked much better then the other birch top, which I only chose because it was in-stock and had few flaws. If I were to make it again, I would use all oak or maple. One thing that did change from 3D model plans was the location of the in/out ports. I moved it to the back instead of the side for more structural integrity. The thing that brought out all the beauty was the coat of satin polyurethane.

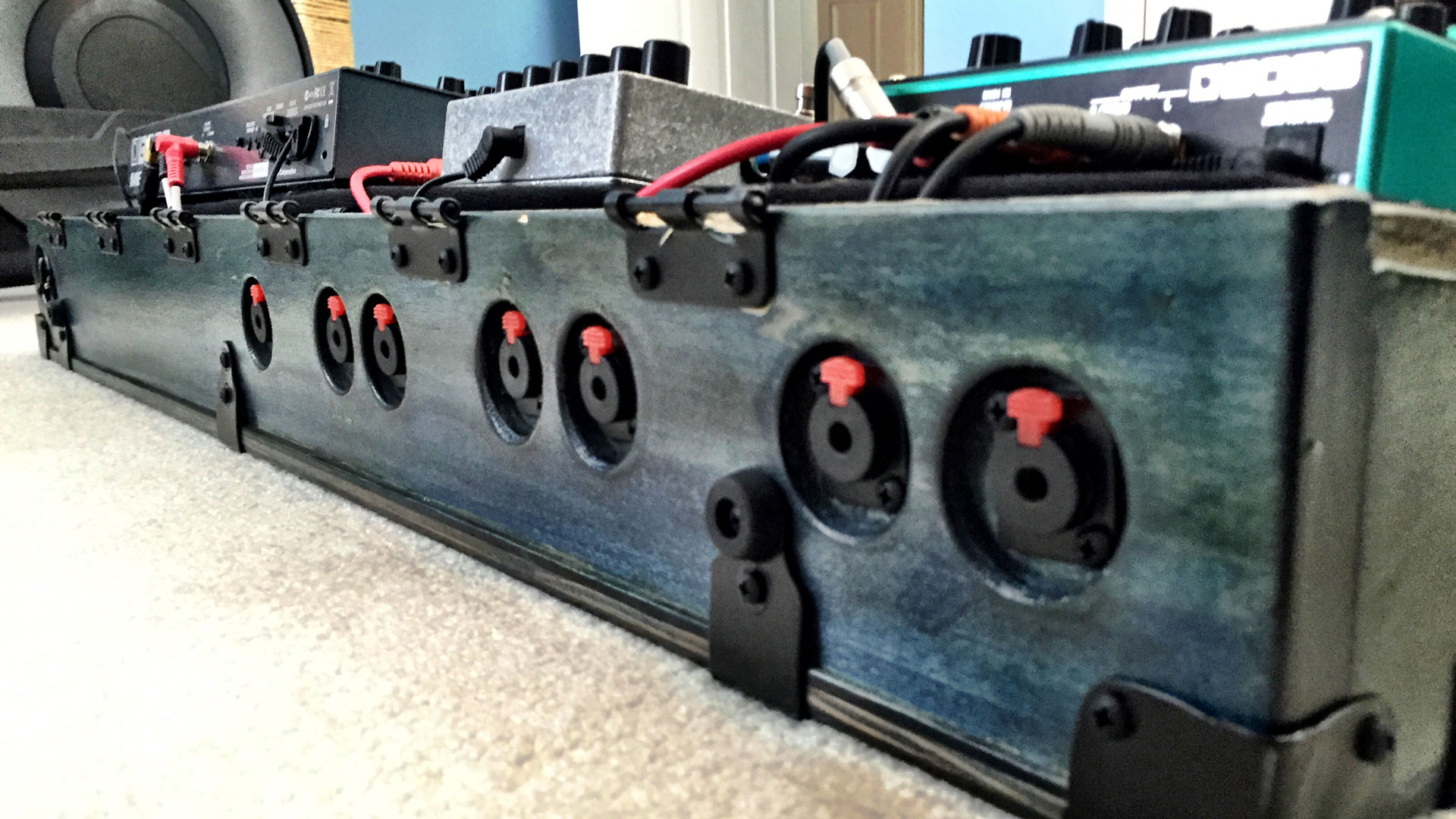

Adding Hardware

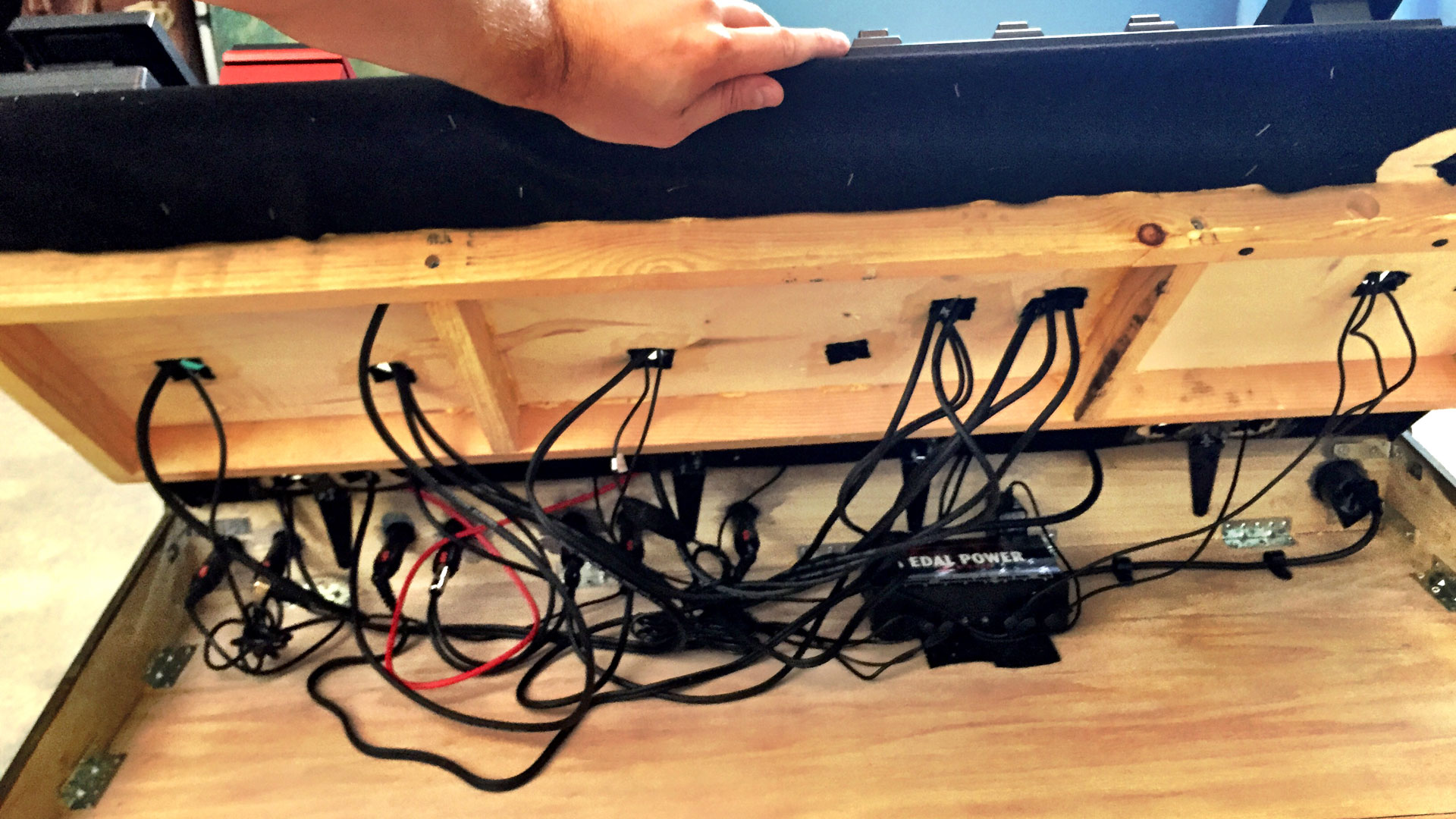

The finishing touches included add hardware, adding loop carpet for velcro pedals, and adding all the necessary wiring and internal power. I wanted to be able to connect devices and power easily to the inside without having to open anything up. The goal was to be able to get setup in 5 minutes. Toting this equiptment around and manually hooking it up would be an inconvenience for any venue.

Conclusion....

Everything works as planned. It is truely an easily portable prewired pedalbox. If you're interested in what I used to make this, here is a pdf with more detailed plans and sources for parts I used.

Thanks for reading.

Some Other Projects...